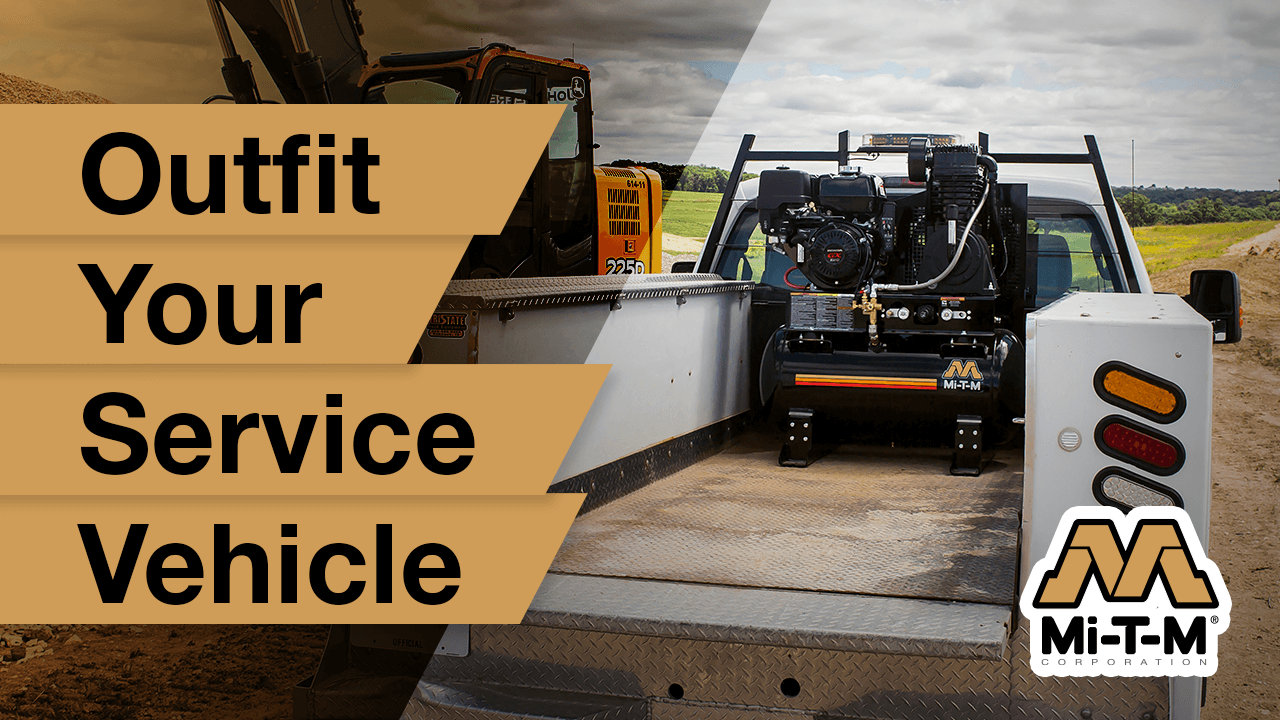

Portable Air Compressors

Featuring advanced technology, Mi-T-M portable air compressors are available in gas, electric and diesel power with a wide variety of tank capacities. Perfect for the contractor who relies on air power and the ability to transport equipment from one jobsite to another.

View Portable Models

Stationary Air Compressors

Often considered the fourth utility, compressed air is essential in many commercial and industrial settings. Mi-T-M manufactures a wide range of stationary air compressors in both horizontal and vertical tank configurations. Each is designed to deliver optimal performance and ongoing reliability.

View Stationary ModelsAir Compressor FAQs

We know air compressors and can help you find the answers to your questions.

What are the advantages of using compressed air vs. other power sources?

The advantages are many and are summarized in the following list:

- Compressed air systems provide operators the ability to control the air supply to meet the system’s demand making it more efficient than other power systems.

- Compressed air systems are easier and less costly to install than electrical grids and less demanding than hydraulic system lines.

- Pneumatic air tools have less maintenance and down time than hydraulic tools.

- Typically, pneumatic tools weigh less than electric tools which makes the tools more ergonomically friendly.

- Using a gas driven portable air compressor allows for more versatility while using pneumatic tools than those tools that need to be plugged into an outlet.

- In most cases, pneumatic air tool’s initial purchase price is less by comparison of electric or hydraulic driven tools.

- Air tools run cooler because the expanded air dissipates the heat of operation as the air passes through the tool. Air tools typically do not overheat and therefore will have less maintenance and downtime.

Does a new compressor have to be broken in?

No, it does not. However after an install, you should power up the system from 0 to whatever the cut-off pressure is and check for any leaks that may be present.

What size of compressor do I need?

In order to determine what size compressor will meet your requirements you need to establish how it will be used. For example, if you will be using it to power air tools, then you need to determine the CFM of each tool. There are many applications for air compressors. If you need help deciding which size is best for you, please contact Mi‑T‑M at 800-553-9053 and we will be happy to assist you.

How much air pressure do I need?

Air pressure is determined by the highest minimum pressure requirement. For example, some tools consume more air than others. Tools such as pneumatic nail-guns and staplers consume smaller amounts of air, while air grinders and sprayers consume larger amounts. Most tools have an usage rating for CFM consumption at a recommended PSI. This can be found on the tool itself or in the owner's manual supplied by the tool manufacturer. Click here to view our Air Equipment Estimating Guide.

Accessories

Accessories

Pressure Washers

Pressure Washers

Air Compressors

Air Compressors

Generators

Generators

Air Compressor Generators

Air Compressor Generators

Air Compressor / Generator / Welders

Air Compressor / Generator / Welders

Portable Heaters

Portable Heaters

Water Treatment Systems

Water Treatment Systems

Trailers

Trailers

Water Pumps

Water Pumps

Wet / Dry Vacuums

Wet / Dry Vacuums

All Residential Products

All Residential Products

All Commercial Products

All Commercial Products

Pressure Washers

Pressure Washers

Generators

Generators

Air Compressors

Air Compressors

Custom Fire Pits

Custom Fire Pits

Portable Heaters

Portable Heaters