Industrial

5 - 120 Gallon

Industrial Air Compressors

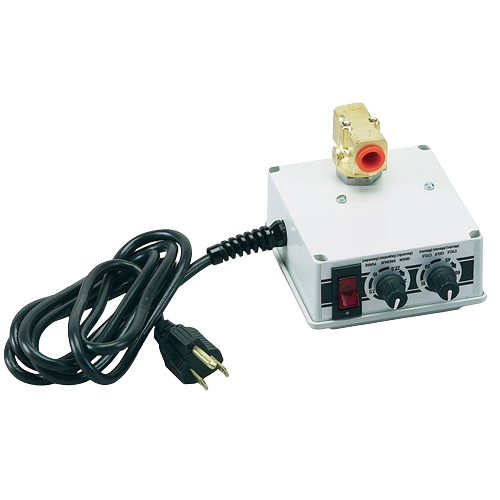

Mi-T-M’s industrial air compressors are manufactured with only the highest quality components and a tough powder coat finish. Their efficient design makes them ideal for many applications in construction, commercial and industrial settings.

View All Industrial Air Compressors

Commercial/Residential

3 Gallon

Commercial & Residential

Air Compressor

Perfect for jobs around the house, workshop or even a jobsite, the MiT-M residential and commercial air compressor delivers reliable air power.

View The Commercial/Residential Air Compressor

Latest Equipment

Latest Equipment

Accessories

Accessories

Pressure Washers

Pressure Washers

Air Compressors

Air Compressors

Generators

Generators

Air Compressor Generators

Air Compressor Generators

Air Compressor / Generator / Welders

Air Compressor / Generator / Welders

Portable Heaters

Portable Heaters

Water Treatment Systems

Water Treatment Systems

Trailers

Trailers

Water Pumps

Water Pumps

Wet / Dry Vacuums

Wet / Dry Vacuums

All Residential Products

All Residential Products

All Commercial Products

All Commercial Products

Pressure Washers

Pressure Washers

Generators

Generators

Air Compressors

Air Compressors

Custom Fire Pits

Custom Fire Pits

Portable Heaters

Portable Heaters