In order to maintain the high quality performance of your Mi-T-M hot water pressure washer, preventative maintenance is crucial. In the video and guide below, we will teach you how to keep your pressure washer working at optimal level and minimize issues.

Steps to Maintain Your Pressure Washer

- First, become familiar with the common parts of your pressure washer and where each is located. While not all pressure washers have the same parts, they have the same basic components.

-

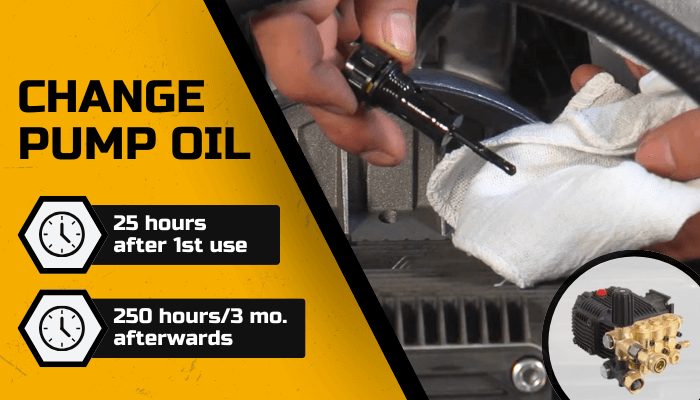

The pump oil should be changed after 25 hours of operation of a new machine. After that, pump oil should be changed every 250 hours or every 3 months. For optimal performance, use Mi-T-M pump oil, and check the oil level before each use.

-

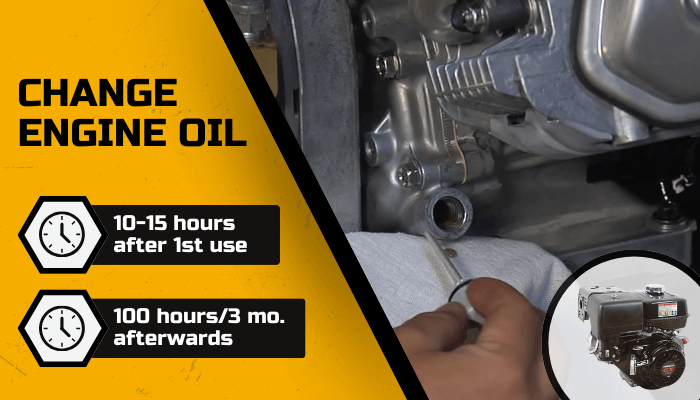

The engine oil should be changed after the first 10 to 15 hours of operation on a new pressure washer. After the initial change, the engine oil should be changed every 100 hours or every 3 months. Use the oil recommended in the engine manual supplied. Always check the oil level before each use.

-

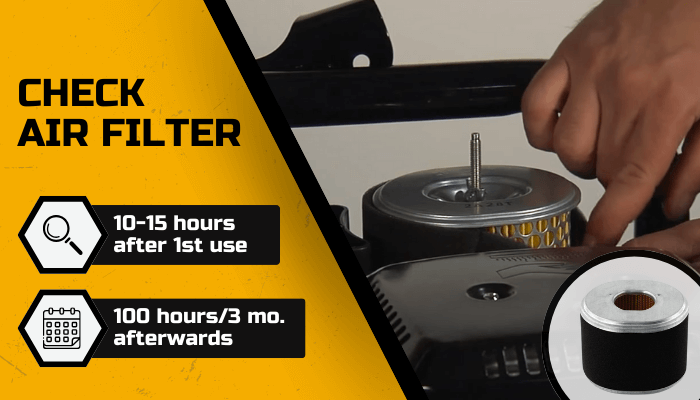

Check the air filter monthly and be on the lookout for dust and dirt that may clog the filter. Be sure to replace the filter every 6 months, or sooner if needed.

-

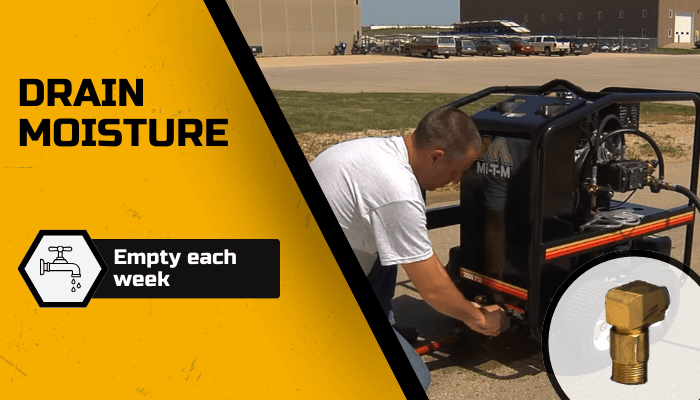

Drain the moisture from the heating coil every week by opening the drain valve.

- The fuel tank should only be filled with clean fuel. If condensation or water accumulates in the fuel tank, open the tank drain and remove water.

-

Replace the burner fuel filter every 3 to 6 months.

-

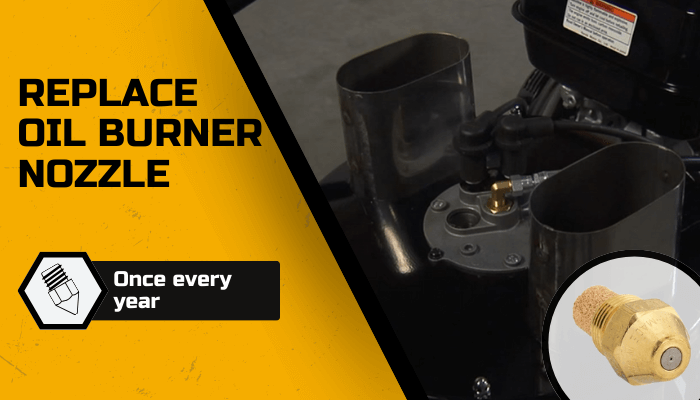

The electrode cone assembly consists of the burner fuel nozzle and burner electrodes. The nozzle cannot be cleaned and should be replaced at least once per year. Make sure the replacement nozzle is the same size.

-

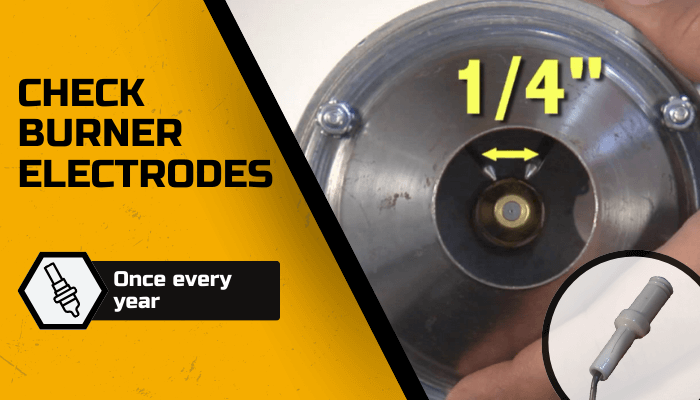

The burner electrodes should be checked and gapped yearly. Based on their condition, they may need to be replaced. Look for ceramic cracks, tips that are not pointed, and a buildup of soot.

-

Heating coil maintenance can be minimized by cooling the unit down properly after each use. Never turn your pressure washer off without first cooling the boiler down. Do this by turning the burner off and squeezing the trigger for approximately 60 seconds or until the metal lance feels cool to the touch.

Need Help?

If you need assistance with your preventative maintenance procedure, get in touch with an authorized Mi‑T‑M service center or the Mi‑T‑M Product Support department.

Latest Equipment

Latest Equipment

Accessories

Accessories

Pressure Washers

Pressure Washers

Air Compressors

Air Compressors

Generators

Generators

Air Compressor Generators

Air Compressor Generators

Air Compressor / Generator / Welders

Air Compressor / Generator / Welders

Portable Heaters

Portable Heaters

Water Treatment Systems

Water Treatment Systems

Trailers

Trailers

Water Pumps

Water Pumps

Wet / Dry Vacuums

Wet / Dry Vacuums

All Residential Products

All Residential Products

All Commercial Products

All Commercial Products

Pressure Washers

Pressure Washers

Generators

Generators

Air Compressors

Air Compressors

Custom Fire Pits

Custom Fire Pits

Portable Heaters

Portable Heaters