In The Spotlight – Nick Slavik Painting and Restoration Co. (What’s New)

Back in the Summer of 2020, we had the pleasure of interviewing Nick Slavik of Nick Slavik Painting and Restoration Co. Nick’s story is one of hard work and dedication to his craft, and Mi-T-M is honored to be a part of the journey and continued success!

As we fast-forward 2 years from our initial interview, things have definitely changed.

What’s new with Nick Slavik and Nick Slavik Painting and Restoration Co.?

- Has your business and team grown since 2020?

- “We have grow to about 40 people + subcontractors.”

- How’s your Facebook Live Series “Ask a Painter” going?

- “AAP is such a fun thing that I originally started to share my life – that of a master craftsperson and a trades business owner. It’s turned into so much more and in the end, I realize that I’d learned so much from the viewers. I would not be where I am today if not for that community.”

Any new & interesting projects you’ve been working on?

- What (specifically) did you enjoy most about those projects?

- “We do many big historic restorations each year. I love the history, the interesting colors and the clients. They are monumental efforts and are super satisfying to undertake! We also painted a custom beer mural on a silo overlooking a baseball field this summer! Its fun stuff like that that gives me a ton of energy.”

- Where are some of the most beautiful places you’ve worked in the last 1-2 years?

- “We’ve been to wilderness cabins, islands in the Gulf of Mexico, San Francisco and Utah. All adventures!”

How has Mi-T-M played a role in your success?

- How many pieces of Mi-T-M equipment do you own?

- “We own about 6 washers.”

- What do you enjoy most about the equipment?

- “Reliable, tough, no hiccups.”

- What are some of the best qualities of your Mi-T-M equipment?

- “I feel like they are sturdy machines – they’re just tough little things.”

- What does the future look like for Nick Slavik Painting & Restoration?

- “We’ve just tipped over the hill of what I would consider a ‘professionalized’ business. We have a full leadership team, a great group of craftspeople and we give clients an awesome experience. My hopes are to maximize the effectiveness of our little freedom machine and create a bunch of opportunities for those involved.”

For more information about Nick Slavik Painting and Restoration Co., you can read the original blog interview from July 2020!

(Original Interview – July 2020)

Nick Slavik has been a part of the painting and restoration industry for 28 years. Starting at such a young age was a challenge for Nick, but once he got to dictate his own path he fell in love. In fact, he loves what he does so much he decided to start up his own company Nick Slavik Painting and Restoration Co. 13 years ago, where he has worked relentlessly to make a name for himself.

Nick Slavik does everything he can to ensure his clients receive the greatest value. He specializes in large residential historic restorations, interior fine finishing, and exterior wood restoration such as decks, fences, and log/wood homes. Slavik and his team also work large scale commercial and industrial projects.

While visiting his local Sherwin Williams store, Slavik first laid his eyes on a Mi-T-M power washer and was instantly impressed. The sturdiness and quality stood out to him, which is why he made his first purchase and never looked back. Looking forward, Slavik now owns three Mi-T-M pressure washers that he uses to facilitate washing and chemical restoration services.

When it comes to choosing his equipment, Slavik does his research, looks for the really good stuff, makes an informed decision then makes the purchase in hopes to never think twice about it. Slavik wants the best for his company. He wants the equipment that is well made, works as advertised, easily maintainable, and never fails. That is why he chooses to continue working with Mi-T-M units and his local Mi-T-M dealer.

“The best compliment I can give these units is that I don’t think about them. They are the most reliable employee I have. Never sick, always overperforms. They never disappoint.”

If Slavik has any advice for future buyers, it’s to “invest in the good stuff and never worry about it.”

Nick Slavik Painting and Restoration Co. is a premier painting contractor for New Prague and the surrounding area. Make sure you also check out their Facebook Live series “Ask a Painter.” This Facebook show is where you can ask questions and Slavik uses his two decades of knowledge to answer. Slavik goes live on this Facebook page every Friday.

Tech Tip: Hot Water Pressure Washer Troubleshooting

Standard HG Hot Water Pressure Washer Troubleshooting

What to do if the burner is not firing and how to check the MV terminal.

The first thing you should do if your hot water pressure washer burner is not firing is to make sure the unit has a pilot flame. If it does, you will then need to check if the ignition control box is seeing the flame correctly. To do this, you will need to locate and check the MV terminal on the hot water pressure washer. Every HEG unit has an ignition control box that is powered with a 24V AC the minute the pressure washer motor starts.

The ignition control box is mounted to the left of the water pump under a black metal cover. When a unit is started, the ignition control will create a spark and open the pilot solenoid on the gas valve to light the pilot flame. Once the ignition control box senses the pilot flame, it will send 24 volts of AC power out through the MV terminal. To check it properly, you will need to use a voltmeter. Place the black lead of the voltmeter on the TR ground terminal and the red lead of the voltmeter on the TH terminal.

So why is the MV terminal so important to check?

Without the 24 volts of AC power that is sent out through the MV terminal, no other part of the burner circuit on the hot water pressure washer will work. It’s the AC power that will power the main valve on the gas valve that’s used to light the burner ring. Regardless of what options are included, all HEG units have the same power circuit process. So, if there isn’t any power that is being sent out through the MV terminal, the sensing circuit on the machine will not be satisfied. You will need to make sure to check this terminal in the first steps of troubleshooting to narrow the variables down to the pilot flame, sensing rod and wire or the ignition control box itself. On isolated occasions, the grounding of the unit can affect the sensing circuits, so keep this in mind while working on these units. Typically, if your ignition control box is sending out 24 volts of AC power through the MV terminal, then the issue could simply be the replacement of a pressure switch or thermostat.

If your hot water pressure washer burner is still not firing after completing these steps, contact an authorized Mi-T-M Service Center or reach out to Mi-T-M Product Support at 800-553-9053.

Tech Tip: Kerosene Forced Air (KFA) Portable Heaters Not Firing

If your Kerosene Portable Heater is not firing, there could be a couple reasons causing this issue.

Possible Cause #1

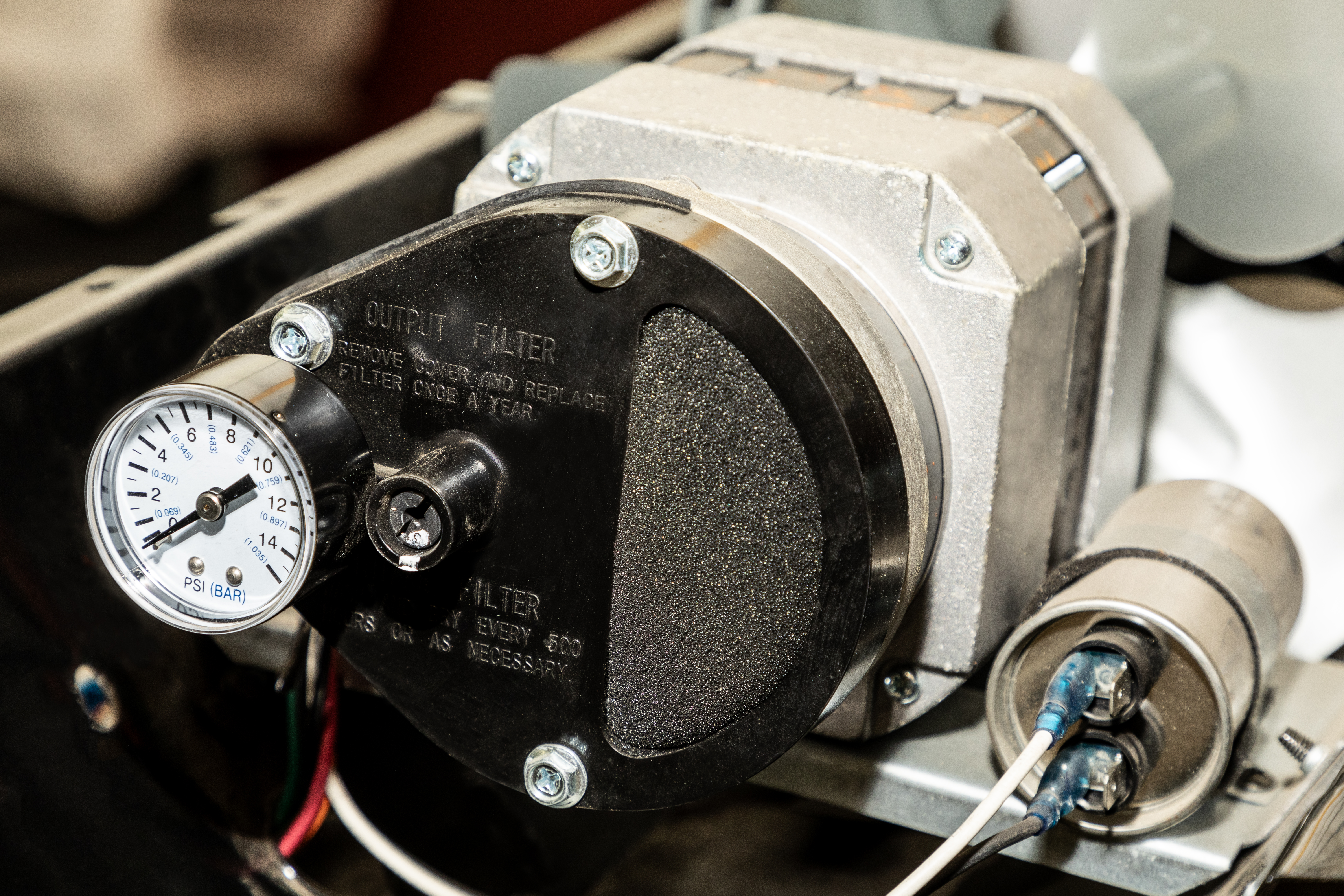

If you are trying to light your KFA Portable Heater and you notice little or no air pressure registering on the pressure gauge, there may be an issue with one of the following components:

1. Air filter

2. Air hose

3. Air pump rotor

Solution:

– Check to make sure the air pump filters are clean.

– Check for a hole(s) in the air hose that connects the air pump to the burner nozzle. If you do not find any holes, remove and inspect the air pump rotor for cracks and damage.

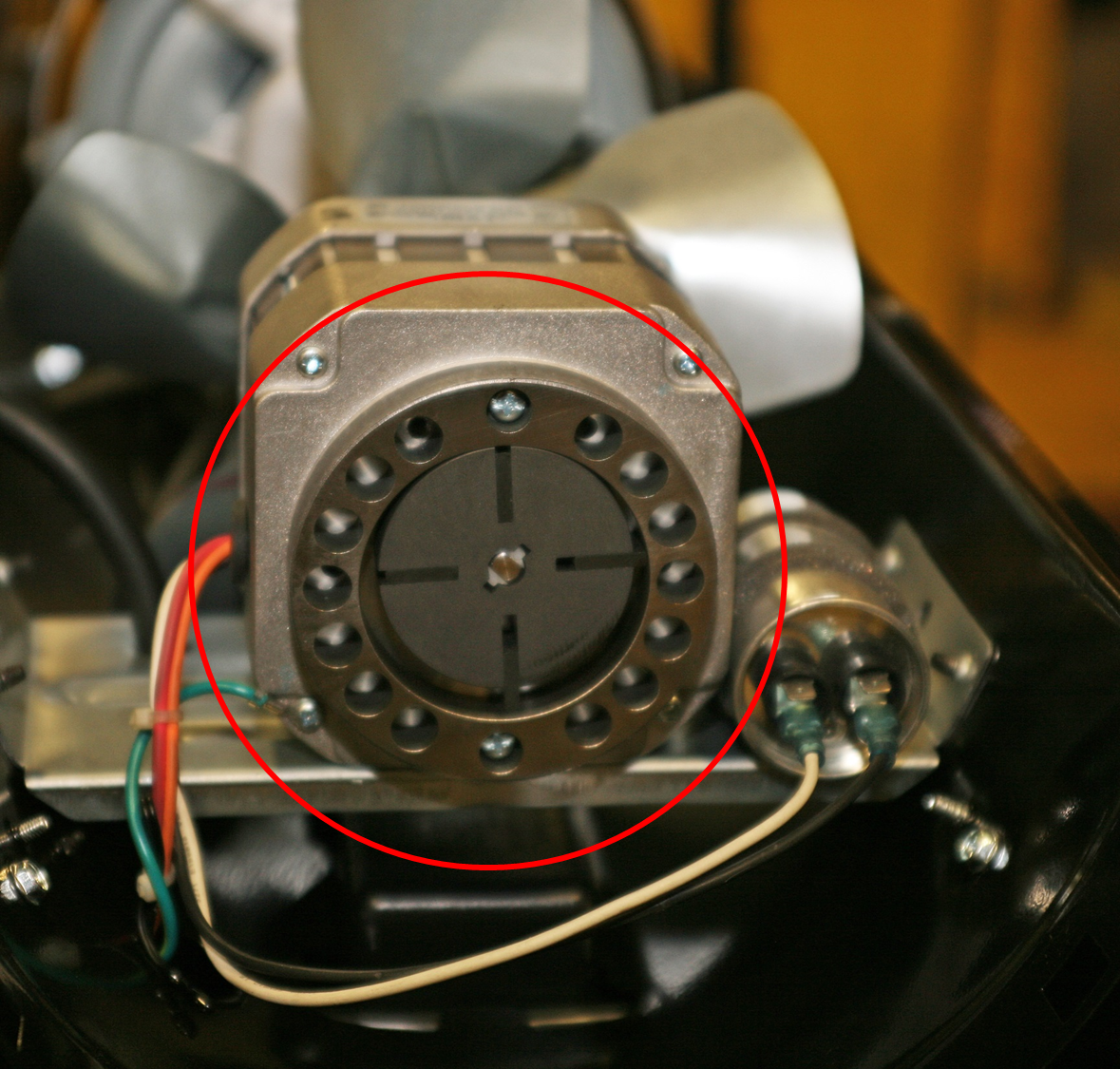

– Replace the air hose or air pump rotor based on the root of the cause. When replacing the air pump rotor, you must set the proper gap at the top of the carbon rotor. To do this have the rotor in place and the outer steel ring loose, then place the .004 inch gauge between the top of the rotor and the bottom of the outer ring. Tighten the bolts in the steel ring.

– Next, rotate the air pump rotor clockwise and recheck the .004 inch air gap every 1⁄4 turn from the same top location.

– Reset the outer ring if any locations are less than .004 inch.

Possible Cause #2

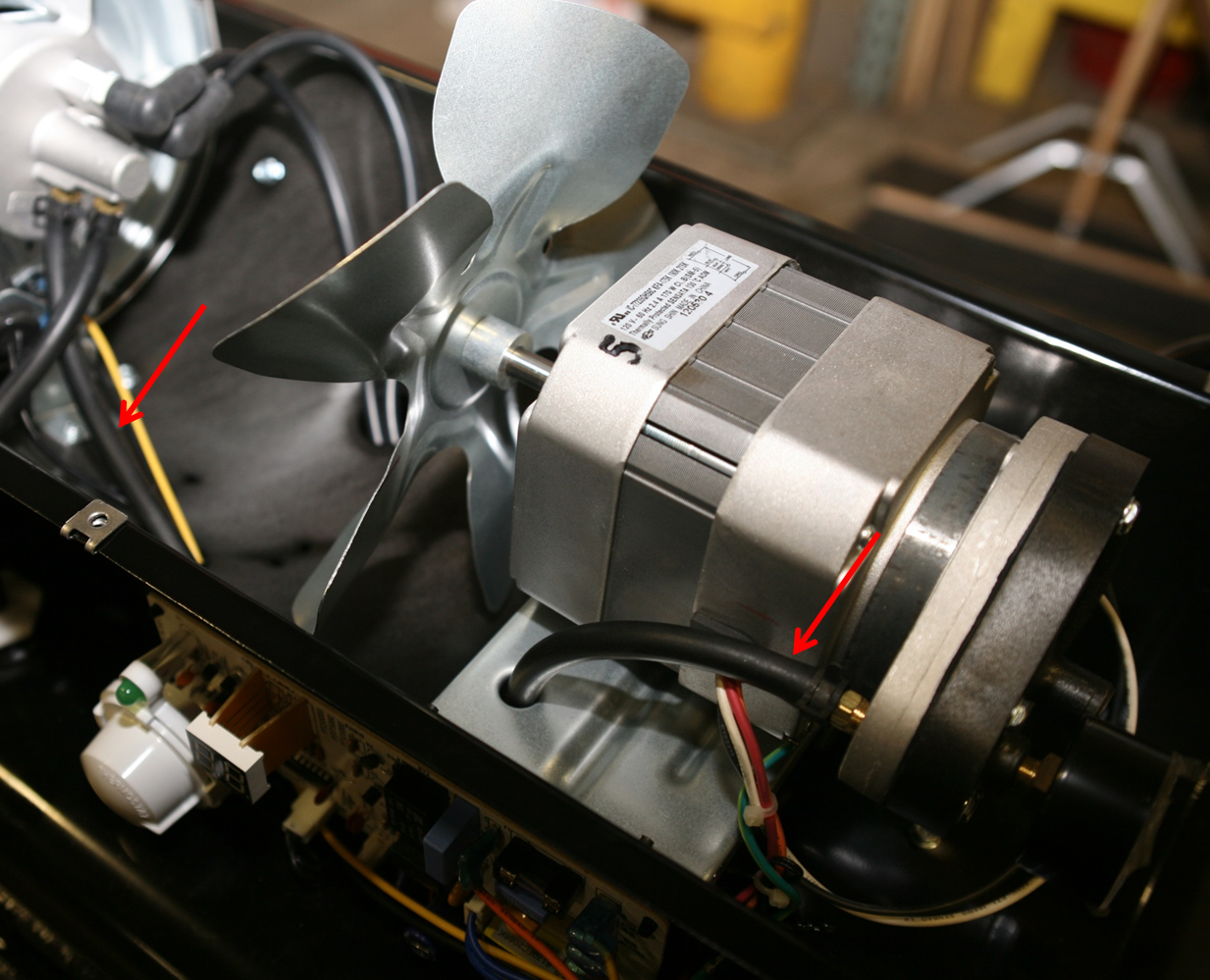

If the proper air pressure is registering on the pressure gauge (see heater decal for proper pressure) and the heater sprays fuel, but you still cannot light up your KFA Heater, there may be an issue with one of the following components:

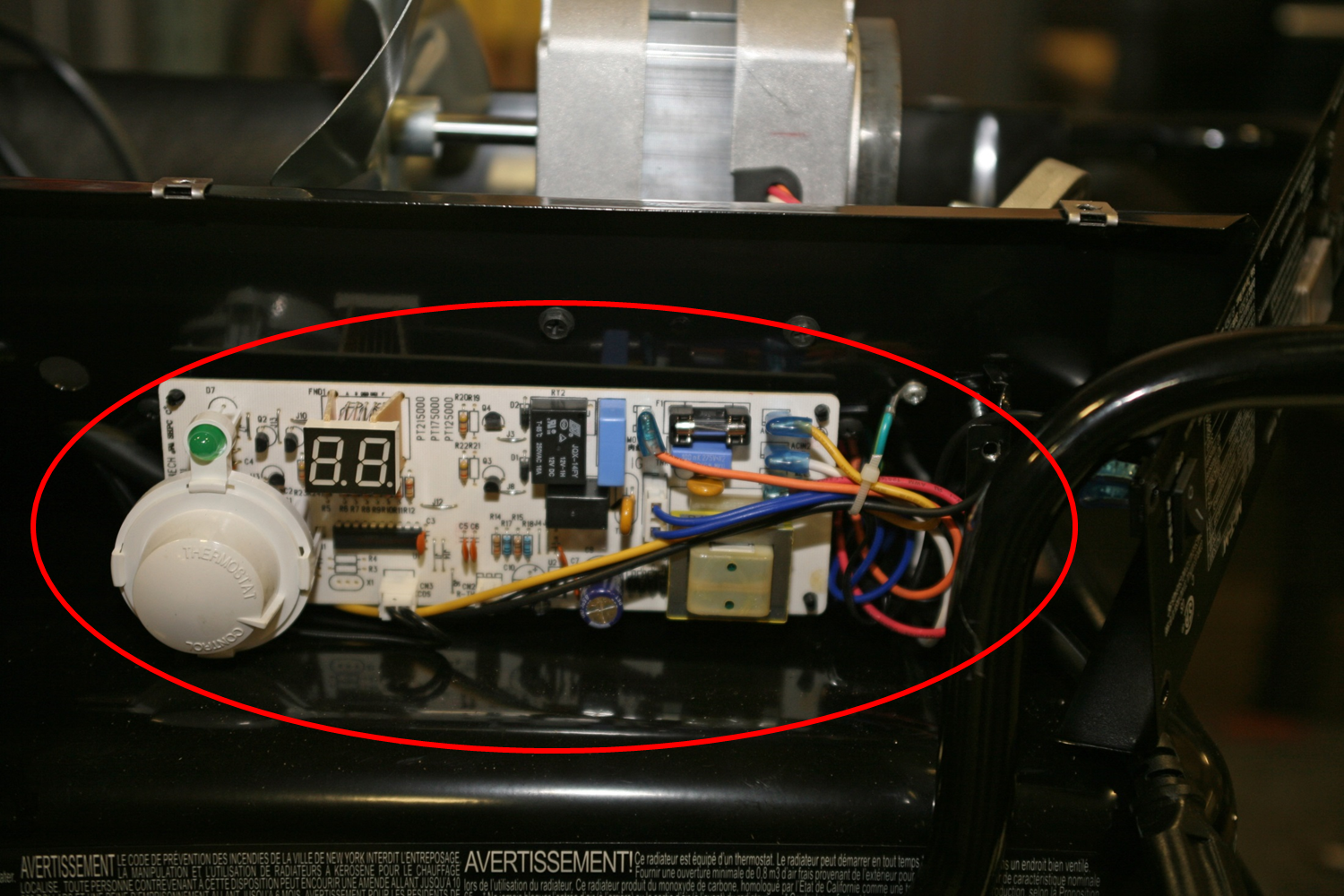

1. Control board

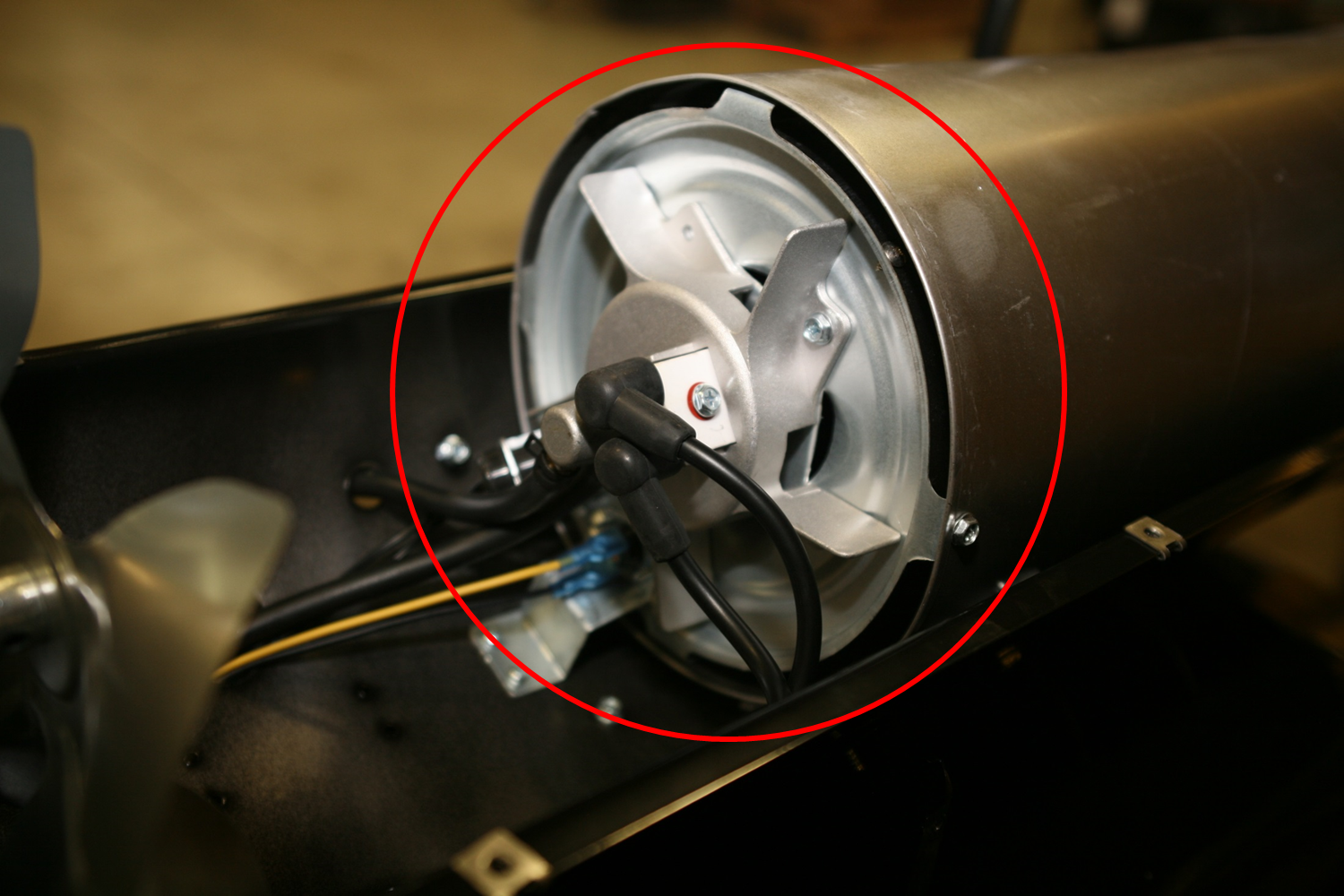

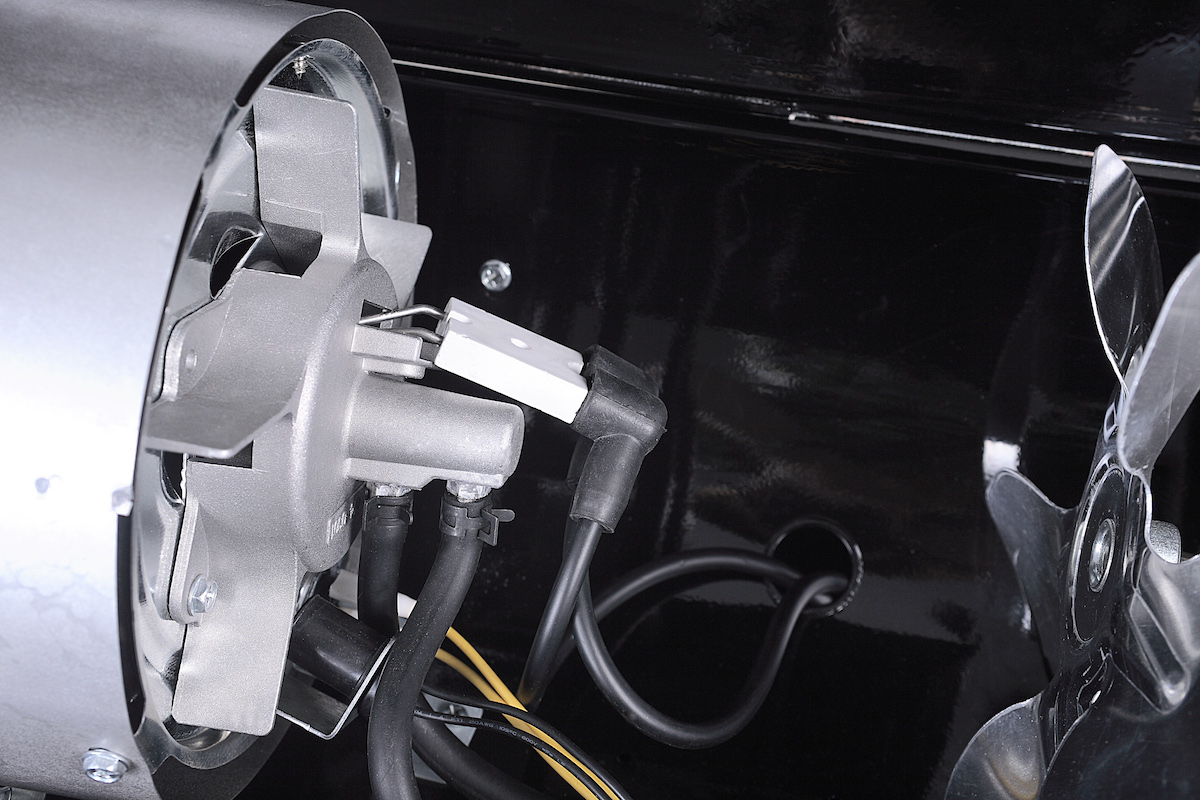

2. Igniter (which is mounted underneath the fan pictured below)

Solution:

Disconnect the igniter wires from the control board and check for voltage on the control board. The voltage will need to be checked within 1 – 3 seconds of turning the heater on/off switch to the on position. The voltmeter should read 120 volts AC. If there is no voltage, you will need to replace the control board. If voltage is present on the control board, that means that your igniter is more than likely the issue and you will need to replace it.

Tech Tip: Portable Kerosene Heaters

Heater Season Again

The most common heaters you will see in the field are the Portable Kerosene Heaters (or Kerosene Forced Air, KFA). To best help you tackle issues with these heaters, new or used; here are some initial questions our Tech Team will ask you.

1)What is your air pressure?

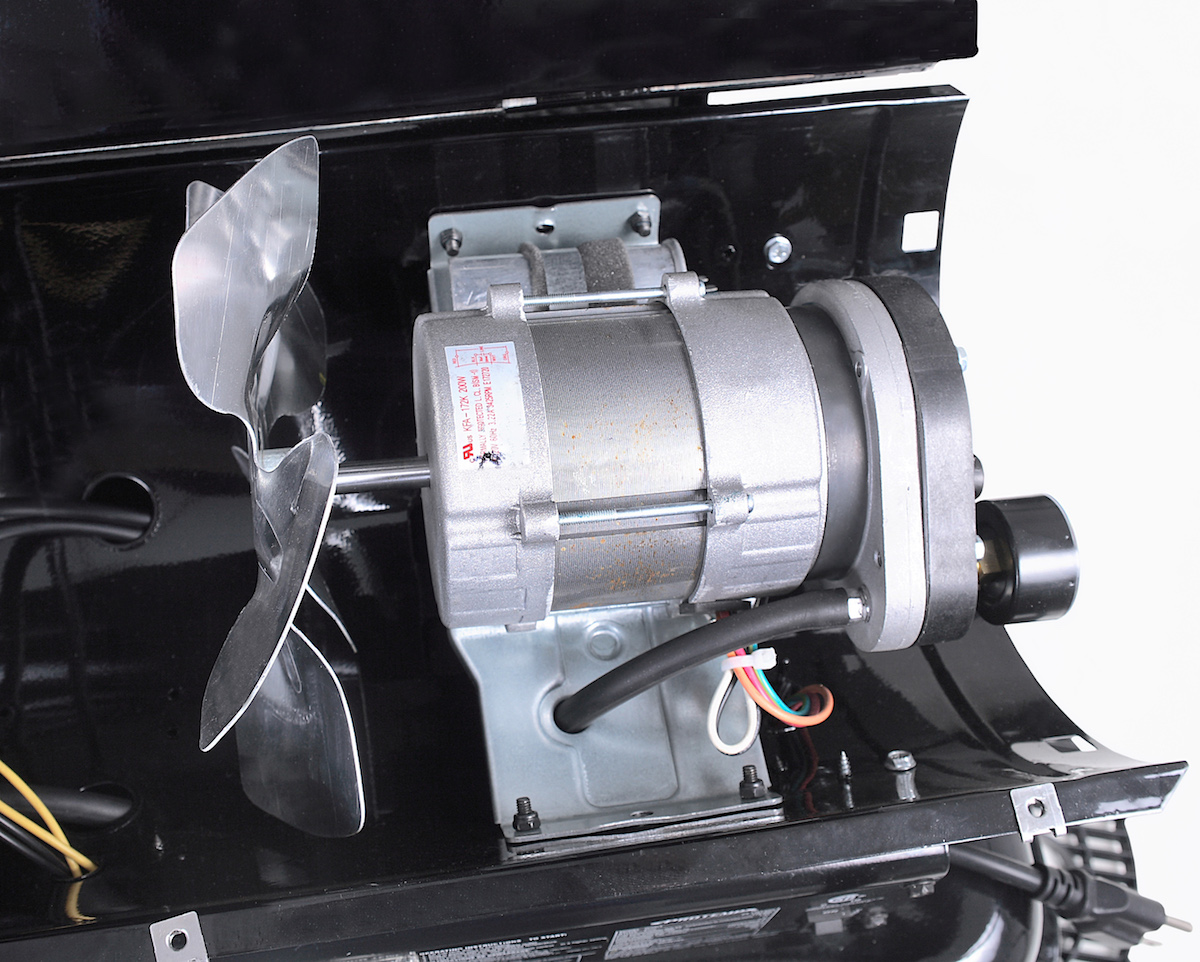

There is a small carbon vain pump on the back of the fan motor that creates air (typically under 10 PSI) that pumps through the burner head creating a venture to lift the fuel and spray (atomize). So if there’s poor or no air pressure, then there’s poor or no fuel atomization.

2) What is the condition of the fuel?

Good and proper fuel is vital. Old or poor fuel can clog up filters, nozzles and not light correctly.

3) Is there a good spark?

At start up, our KFA Heaters will have spark for 20 seconds. The spark is only for initial lighting; the flame stays lit based on proper air and fuel balance.

4) Is the heater lighting?

If the heater is lighting and how the heater is shutting down are very important indicators. For example, the most common heater problems is when the heater will start, light, run for a few seconds or minutes and then shut down and smoke. Any smoking is a sign of incorrect fuel/air mixture and in most cases is caused by poor fuel atomization at the nozzle. After double checking the air pressure, we would recommend new fuel, a new fuel filter, and cleaning or replacing the fuel nozzle.

For more information on equipment service or repair, visit our service locator here.

Latest Equipment

Latest Equipment

Accessories

Accessories

Pressure Washers

Pressure Washers

Air Compressors

Air Compressors

Generators

Generators

Air Compressor Generators

Air Compressor Generators

Air Compressor / Generator / Welders

Air Compressor / Generator / Welders

Portable Heaters

Portable Heaters

Water Treatment Systems

Water Treatment Systems

Trailers

Trailers

Water Pumps

Water Pumps

Wet / Dry Vacuums

Wet / Dry Vacuums

All Residential Products

All Residential Products

All Commercial Products

All Commercial Products

Pressure Washers

Pressure Washers

Generators

Generators

Air Compressors

Air Compressors

Custom Fire Pits

Custom Fire Pits

Portable Heaters

Portable Heaters