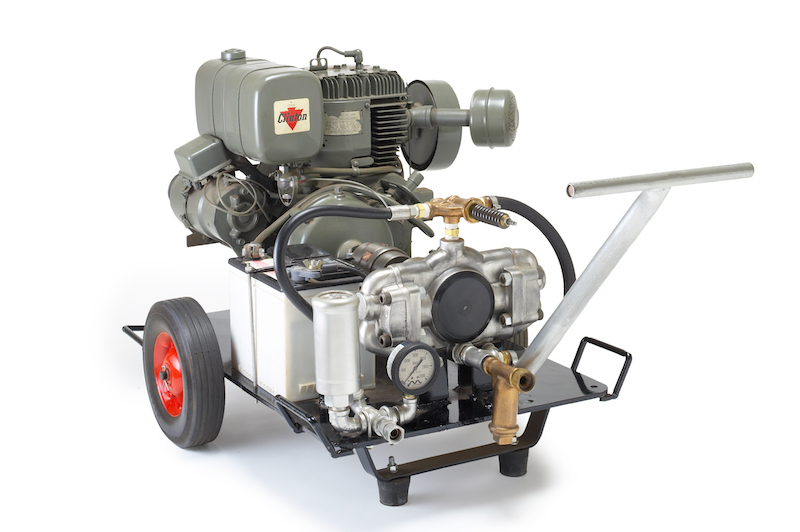

Mi-T-M Trash and Semi-Trash Pumps

What We Offer

Mi-T-M offers trash and semi-trash pumps that are designed to efficiently move hundreds of gallons of water and waste per minute. Whether you’re dealing with construction site dewatering, flooding, sewage challenges or any other water-moving task, our water pumps are readily available to make these tedious tasks a breeze.

The Mi-T-M semi-trash pumps come in either a 2 or 3-inch suction and discharge size with a suction lift of 28-feet, while trash pumps come in either a 3 or 4-inch suction and discharge size with a suction lift of 26-feet.

Our water pumps are equipped with heavy-duty powder coated wraparound frames and rubber isolators, along with silicon carbide mechanical seals, an industrial OHV engine and cast-iron impeller for reduced vibration. Whether it’s the robust construction materials or the reliable engine powering pump, you can trust our equipment will perform consistently in demanding environments, ensuring reliable service life and longevity.

Our water pumps are engineered to deliver exceptional flow rates, effortlessly handling large volumes of water and waste including debris, sludge and solids up to 1-inch in diameter. From construction sites to industrial applications, our pumps keep things flowing smoothly.

Application Versatility

Our trash and semi-trash pumps are tailored for a range of applications to meet the diverse needs of our customers, and are a go-to solution for any task that involves the quick and efficient movement of water and waste.

Some common applications include:

- Flood Control: Remove standing water, along with leaves mud and small debris from flooded areas.

- Emergency Cleanup: Water pumps are essential for removing water in the aftermath of natural disasters.

- Dewatering: Efficiently remove water from areas like swimming pools, basements and excavation sites.

- Wastewater Treatment: Pumps can be used in sewage facilities to move sludge to various treatment processes.

When it comes to efficiently moving large volumes of water and waste, our trash and semi-trash pumps stand above the rest. With high flow rates, solid-handling capabilities, durability and versatility, these pumps are the ultimate solution for all your water management needs.

Experience unparalleled performance on your next project. Contact us at (800) 553-9053 or find a Mi-T-M Dealer near you to get yours, today!

Mi-T-M Gift Guide 2023

What do you get for the person who has everything?

Mi-T-M has the most priceless gift of all: peace of mind.

Mi-T-M offers a number of essential products for any home or business owner, especially for gift giving this holiday season, to help ensure safety and cleanliness for years to come.

Residential Pressure Washers

Clean your property with confidence by investing in a Mi-T-M pressure washer. With a variety of models to choose from, there’s no doubt we have the right tool to get any job done.

ChoreMaster Series: CM-1400-0MEC, CM-1400-1MEH

These lightweight ChoreMaster Series pressure washers are ideal for light-duty cleaning around your home, such as cleaning outdoor furniture, washing small vehicles (including motorcycles or bicycles!) and surface cleaning for your deck and driveway.

ChoreMaster Series: CV-2600-3MMC, CV2600-4MMC

For a little more oomph to your clean, the 2600-PSI ChoreMaster series gasoline models will provide a thorough clean for your car, truck or boat, and have the power to remove dirt and mildew from the siding of your house. They also can be used to prep surfaces for painting.

Wet/Dry Vacuums

Now that we’ve cleaned the outside… let’s go inside… Mi-T-M’s wet/dry vacuums come in handy for those extra fun cleaning jobs that your standard home vacuum may not be able to handle. There are a number of applications for a Mi-T-M wet/dry vacuum around your home or business, including:

- Water cleanup: in your basement, bathroom or other areas

- Garage/workshop cleaning

- Fireplace ash removal

- Pet hair removal

- Car cleaning

- Leaf and yard cleanup

- Appliance maintenance: keep our appliances clean and running efficiently

Portable Generators

Last but not LEAST a Mi-T-M Inverter Generator makes for a great gift. We oftentimes think of generators as backup power for emergency situations. While emergency situations are an important application for Mi-T-M generators, our generators can also be used for fun and leisure like powering a campsite, tailgate or that new food truck you’ve been dreaming of opening.

Inverter Generators: GEN-2000-IMM1, GEN-2500-IMM1, GEN-3500-IMM1

These inverter generators are small, but mighty – they are the perfect, compact size to pack into your vehicle for your next fall camping adventure or outdoor tailgate. No need to worry about that annoying generator hum, these inverter generators are equipped with quiet technology so your conversations go on uninterrupted. For your safety, these inverter generators are equipped with carbon monoxide detection and auto shutdown, so you can focus on having fun, while they keep you safe.

ChoreMaster Series Generators: GEN-3600-0MM0, GEN-6500-0MM1, GEN-8000-0MM1E

Our ChoreMaster Series of generators are for when you need more heavy-duty power — coming in at up to 8000-watts, these generators provide reliable backup power for your home essentials, in case of a storm. They can also provide power to a small cabin for those special getaway weekends. Plug in and charge up this season with a ChoreMaster Series Generator.

From all of us at Mi-T-M, we wish you a safe and happy holiday season. For questions about products featured in this article, contact us on our website or give us a ring.

Mi-T-M Wet/Dry Vacuums Applications

In the world of industrial cleaning, efficiency and versatility are paramount. Dust, debris and spills are a common occurrence and the need for a reliable cleaning solution is undeniable. This is where wet/dry vacuums make the difference and Mi-T-M offers some of the quietest on the market. They are ideal for residential applications, home workshops, jobsites and repair shops, and come in 9, 13 or 18-gallon models.

All three models of wet/dry vacuums from Mi-T-M have a self-cooling motor design with quiet operation. They have multiple uses around the home or workshop:

- Dry Debris Cleanup: Whether it is dust, metal shavings, wood chips or other dry particles, wet/dry vacuums are designed to handle it all. They come equipped with powerful suction and efficient filtration systems to capture fine particles and larger debris.

- Liquid Spill Cleanup: Liquid spills are bound to happen in residential and industrial settings, and when they do, you need a vacuum that can swiftly and safely clean them up.

The versatility of wet/dry vacuums make them indispensable in various applications. Some common applications include:

- Residential: wet/dry vacuums make residential chores more manageable including general household cleaning, garage cleanup, vehicle detailing, pet cleanup and more.

- Manufacturing Facilities: wet/dry vacuums can be used to efficiently clean dust and debris built up during the manufacturing process to ensure a safe and clean workspace.

- Construction Sites: wet/dry vacuums can be used to easily remove anything from dry construction dust to wet cement or paint spills.

- Automotive Workshops: wet/dry vacuums can be used to both detail vehicles and to clean up other debris that are common in automotive repair shops.

- Food Processing Plants: wet/dry vacuums can be used to clean up wet and dry food particles, keeping food processing plants clean and in compliance.

- Warehouse and Distribution Centers: wet/dry vacuums can be used to clean a wide range of materials in warehouse and distribution centers.

Mi-T-M’s wet/dry vacuums multi-functionality and efficiency reduces the need for multiple cleaning tools, saving time and effort. They are an essential tool for maintaining clean and safe residential and industrial work environments.

Mi-T-M’s knowledgeable Sales Support Team are available to answer any questions and will help you find the right size wet/dry vacuum for your specific needs. Contact us at (800) 553-9053 or find a dealer near you.

Mi-T-M Corporation Manufactures Industrial Equipment in Peosta, Iowa.

Made In The USA

The ability to work and provide value to a company, community and neighborhood has given Americans a certain purpose for generations. Mi-T-M Corporation’s employees are proud to be part of a team that builds American-made products.

The Mi-T-M brand is well known around the world for high quality products and unequaled workmanship. The industrial grade equipment is used across many industries by paint and construction contractors, farmers, steel workers, homeowners and even the United States government.

Mi-T-M was founded in 1971 by A.J. Spiegel, a professional paint contractor who saw the need for a portable pressure washer. Mi-T-M’s flagship product is a 1000-PSI cold water pressure washer called the “Mighty 1000.” The name was soon abbreviated to “Mi-T” and paired with the Roman numeral “M” for 1000, A.J. Spiegel had a unique name for his new company…Mi-T-M.

Over 400 loyal and hard-working employees uphold the Mi-T-M Promise “to deliver unmatched performance from the quality of our products to the dedication of each employee who does what’s right for our customer — every time.”

What started as a dream, is now a world-renowned American success story. Today, Mi-T-M manufactures thousands of products in a facility that includes a fabrication division to shape and paint the framework from raw steel. These parts are delivered to 26 production lines where components are assembled. The 1-million square foot facility also features two engineering test rooms, one certification test room and one service test room to ensure the quality of every product before it is shipped out the door.

In 2021, just in time for his company’s 50th Anniversary, A.J. Spiegel announced the sale of his company to his employees. Mi-T-M became an ESOP (Employee Stock Ownership Plan) to not only continue as a privately owned company, but to also ensure it remained part of the local community. Mi-T-M employee’s ownership in the company will provide purpose for generations to come.

Wash Bays – Efficient And Effective Heavy Equipment Cleaning

Mi-T-M wash bays are built for industrial and commercial equipment cleaning with the added benefit of keeping customer operations within compliance.

How Wash Bays Work

Work vehicles and equipment enter the wash bay area and are either sprayed off by a pressure washer or water cannon, rinsing off dirt, grime and grease. Angled to catch the dirty water, the catch basin is below the wash pad and leads to a water treatment recycling system. The contaminants are separated from the water and drained into a disposal system, while the water is stored separately for future reuse.

Alklean Industries, Inc. in Pasadena, Texas.

What It Contains

Efficiently and effectively clean trucks and equipment using an on-site wash bay. By rinsing away excess mud, oil and other contaminants, vehicles can run better, and equipment can function properly and last longer. Within a wash bay, there is a wash pad, pressure washer, catch basin, recycling machine and disposal system.

Exterior photo of a wash bay located at Southern Environmental Equipment in Leesburg, Florida.

Save Money while Saving the Environment

Wash bays provide the ability to clean equipment, while disposing of wastewater safely. Contaminants washed from general work site equipment can have a harmful effect on the environment, but by using a wash bay, it collects the pollutants and keeps them from spreading. After dirty water is run through the recycling system, it can be stored and re-used.

A water treatment system, catch basin and wash pad from Southern Environmental Equipment in Leesburg, Florida.

Types of Wash Bays

Wash bays can be permanent or mobile, depending on what you need it for. For sites that are temporary, a portable wash bay can help clean what you need throughout the duration of that site’s location. No matter the type of wash bay you choose, you can depend on it to properly recycle dirty wash water and dispose of its contaminants.

To help you decide on the specifications your wash bay will need, Mi-T-M’s dealers have the knowledge to assist you. By designing, supplying and installing your new wash bay, you can have peace of mind knowing it was completed by the experts. From start to finish, our dealers will be there to answer any questions you may have along the way.

In The Spotlight – Chamberlain and Company Custom Painting LLC

After a decade working in the custom painting and pressure washing industry, Matthew Chamberlain started his own company Chamberlain and Company Custom Painting LLC in 2009.

Chamberlain is a staunch believer in pressure washing as a necessary first step in exterior painting, and his company prides itself on using the best quality products and equipment in their business.

He started using Mi-T-M equipment in 2015 and currently has two Mi-T-M pressure washers, a Mi-T-M propane heater, and a Mi-T-M rotary surface cleaner.

“Mi-T-M equipment is so easy to use, from start up to shut down,” says Chamberlain. “The quick connect accessories and attachments are effortless. Being introduced to the rotary surface cleaner was a game-changer. It cuts down on wash time and labor tremendously. If there is an use or need, Mi-T-M has a solution.”

Chamberlain and Company Custom Painting purchases all of their Mi-T-M equipment through their local Sherwin-Williams store. The one time they needed to call Mi-T-M customer service, Chamberlain was impressed with the attention and fast support, “It’s obvious that contractors are important to Mi-T-M.”

Chamberlain recommends to anyone using a pressure washer to, “Always do research on the substrate to be cleaned and the chemicals you plan to use.”

Their unique service, a Complete Garage Make-over, offers a full custom painting of garage walls and ceilings, and install epoxy or VCT tile flooring, making your garage personalized to your taste.

Chamberlain and Company Custom Painting serves the Delaware, Maryland and Pennsylvania areas and offers many interior and exterior services, including drywall repair, cabinet refinishing, and deck maintenance.

Maintaining The Indianapolis Motor Speedway: The Tale Of Quipco Sales.

The crowd gathers during the pregame ceremonies at the 2018 Indianapolis 500, May 27, 2018. A B-2 Spirit performed a flyover before the start of the race. (U.S. Air Force photo by Staff Sgt. Joel Pfiester)

The Indianapolis Motor Speedway is a 2 1/2 mile stretch of road that has led many drivers to greatness. There are many unique things about this place, an obvious one being the prestigious Indy 500. Although many events around race day are well documented, many don’t consider the extensive work that takes place before, during, and after. We’d like to give you an insider’s look at what it takes to keep the Indianapolis Motor Speedway in pristine condition for drivers and spectators alike.

As a young boy Daniel Porterfield would ride his bike to the track so he could witness all the action happening on race day. Years later he took over the company his parents founded Quipco Sales and began selling Mi-T-M power washing equipment; because of the contacts he made when visiting the track, Daniel was able to establish the Indianapolis Motor Speedway maintenance crew as his clients. This relationship continued to grow over the years, and in 2016 proved to be fruitful for both sides. Internal factors lead to a track management vacancy at IMS, and Daniel was notified immediately once the contract became available. A relationship that began over 25 years ago resulted in Daniel earning a contract to power wash the Indianapolis Motor Speedway, which is a testament to properly serving clients.

From April 1st to May 25th, Daniel put in 12 hour days of power washing with Mi-T-M equipment before and after each race. One can imagine the amount of cement, concrete, asphalt, composite, and black concrete that’s washed at a racetrack, but picture doing it all by hand. Walking the track with 5,000-gallon water trucks, and spraying it from the top of the bank to the infield seemed to be a never-ending task. As all innovative business owners do, Daniel is currently developing a customized 96-inch truck mounted sprayer to make his operation more efficient the next time around. An improvement such as this could cut his man-hours substantially, and ensure he produces an even better result.

Aside from cleaning the racetrack areas, Daniel is responsible for the washing and sanitizing seating, amenities, and other highly traveled areas. The 250,000 bleacher seats at IMS were cleaned throughout the racing season as well as restrooms, concessions, and concourse areas.

Quipco Sales was founded on the principals of professionalism, trustworthiness, and service, three elements that help to continually strengthen customer relationships. One piece of advice Daniel has for other contractors is, “if possible, always communicate with others on the jobsite. You never know where you’ll make a friend or gain a customer – which are the same thing in my book.”

We love to hear great stories like this from our dealer network and those using our machines to do great work. If you have a story to share with us, please contact us on Facebook.

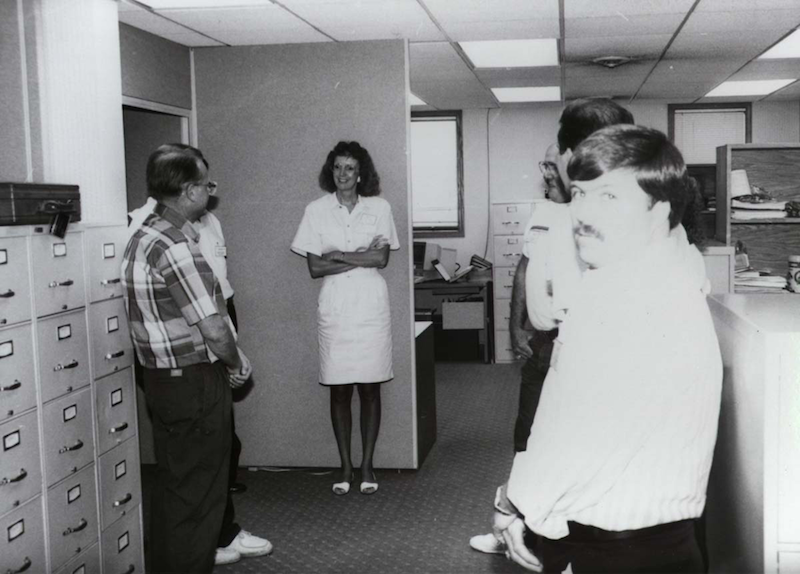

Congratulations Becky Kremer

We want to extend the warmest of congratulations to Becky Kremer on her retirement from the company! Becky started on June 14, 1976. We talked with her below on her experience at Mi-T-M and what she plans to do now:

What was your first position at Mi-T-M?

Secretary – It included secretarial, receptionist, bookkeeping, purchasing, anything related to office work. When I was hired it was just AJ, I and one other guy (Jerry Brimeyer) in the office and there were just a couple guys in the shop.

What is your current position at Mi-T-M?

Sales Administration Manager

Is there one memorable moment or outstanding memory from Mi-T-M that you’ll always remember?

One would be AJ calling from the road and asking “Where am I?” because he was travelling so much. Another memorable time is when we starting making terrific sales. When I was first here, there were months when we were lucky to sell a couple units. It was such a shock when we started having single days when the sales equaled annual sales for some of our early years. I am still amazed at some of our sales days and where all that equipment goes.

What are you plans after retirement? Or what are you looking forward to doing once you retire?

The summer will be spent with the grandkids. We will spend quite a bit of time at our timber (especially my husband). Mostly I am looking forward to relaxing and not feeling rushed to get things done.

For people just starting at Mi-T-M, what would you say to them or tell them? (advice, tips, guidance, etc.)

Mi-T-M is a great place to work. You can tell by the number of employees who have been here for so many years. If you have any questions, there always is someone there to help you out.

Anything additional you’d like to mention?

While I am really looking forward to spending time with my husband and family, I am going to miss my Mi-T-M family terribly. When you have been together for as long as some of us have been, you develop a bonding relationship. I think some people here are aware that in December, it hit me hard that I was actually going to be leaving Mi-T-M and how much I will miss the day-to-day interaction with these special people. However, as retirement nears I am really looking forward to this new phase in my life.

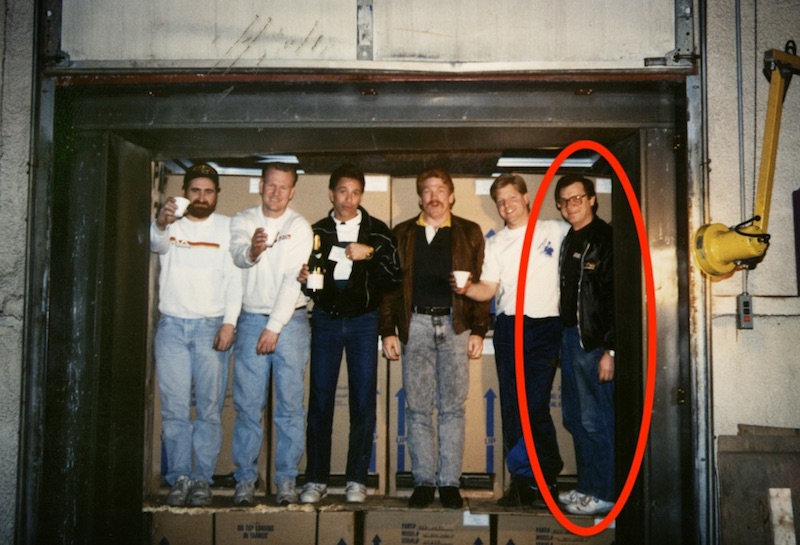

Congratulations Chuck Kluesner

Chuck Kluesner

Hire Date: May 23, 1984

What was your first position at Mi-T-M?

I was hired as an assembler of hot water pressure washers. Mi-T-M had just started the production of these units. From production, I went to the parts department, then worked in shipping and receiving and now I’m just in shipping.

What is your current position at Mi-T-M?

Shipping Supervisor

Is there one memorable moment or outstanding memory from Mi-T-M that you’ll always remember? If so, what is it?

Desert Storm is something I’ll never forget. We worked 12-18 hours a day for 10 days to build those 2000 machines. On the last day we worked 25 1/2 hours straight and after, AJ made a toast to celebrate and then told us all to go home and get some sleep. Over all the whole experience of working at Mi-T-M is memorable; seeing the expansion of the company over the years; going from shipping nothing to now – it’s an astounding difference.

What are you plans after retirement? Or what are you looking forward to doing once you retire?

I’m looking forward to yardwork and gardening, fishing, spending time with the grandkids, relaxing and taking trips.

For people just starting at Mi-T-M, what would you say to them or tell them? (advice, tips, guidance, etc.)

Mi-T-M is a good company to work for.

Congratulations Tom Woerdehoff

Tom Woerdehoff

Hire Date: August 1, 1988

What was your first position at Mi-T-M?

My first position was in sales.

What is your position at Mi-T-M?

I’ve been Credit Manager for 26 years.

Is there one memorable moment or outstanding memory from Mi-T-M that you’ll always remember? If so, what is it?

Actually there are a couple. In the early nineties AJ would strap on roller blades and do laps around the plant at the Kapp location. After production left you could find him out there in the low light having fun. It always brought a smile to my face. He should dust them off and go at it again. Another was whipping up a batch of homemade Irish Cream a couple days before Christmas and bringing some in to share. It became a tradition and I was pleased that I was able to add to the holiday spirit. And finally, all the people that have passed through this great company on their way to somewhere else. There have been many and most have left strong contributions and fond memories.

What are you plans after retirement? Or what are you looking forward to doing once you retire?

I prefer to not call it retirement but an opportunity to do other things. Too much to mention in this small space!

For people just starting at Mi-T-M, what would you say to them or tell them? (advice, tips, guidance, etc.)

Enjoy what you are doing and try to find a reason to laugh and share humor. Look up Donnie Holdridge; he is always good for a laugh. Do the best work possible. There were many who came before you who I’ve had the pleasure to know and who took pride in their work. They are the reason Mi-T-M is as great as it is. Build on that.

Anything additional you’d like to mention?

I do need to thank AJ, Sam and Tom Allendorf for the opportunity to work here and contribute all these years. I am very grateful. Best wishes to all the friends I have made throughout my time here. Many have been with me since the beginning and I cherish the memories. I look forward to keeping in touch – but maybe in the future that can be over a beer and a pool table.

Karen Steger -The “Voice” of Mi-T-M

In the spirit of Administrative Professional’s Day, we’d like to introduce you to one of the most recognizable voices of Mi-T-M. For 26 years, customers have been greeted by the warm and friendly voice of Karen Steger – a humble employee who refers to herself as, “just the receptionist.”

As a potential customer’s first point of contact, it’s crucial for Karen to provide the highest quality customer service possible. Karen is the voice of Mi-T M which means she is also the first person many customers speak with when they call. She is on the front lines of giving every customer the best experience possible, each and every time.

Karen has had the pleasure of meeting many loyal Mi-T-M dealers and customers face-to-face when they come to the Mi-T-M Headquarters. Meeting customers and dealers in person allows Karen to distinguish who is calling just by the sound of their voice. Mi-T-M always strives to make every customer feel like the #1 priority of their company and Karen makes sure that happens with each interaction.

Karen has made many great memories at Mi-T-M that she’ll be able to reflect on for years to come. From being featured on the company calendar twenty years ago to a recent trip to Mexico where she was able to strengthen relationships with Mi-T-M dealers.

Customers of Mi-T-M equipment stay with us because of amazing employees like Karen and the quality products we create.

Preserving The Monuments That Honor Our Veterans

Ponsford Ltd., is the most unique conservation group in the United States and has been using Mi-T-M equipment for over 25 years. Ponsford has developed into a highly regarded conservation, restoration, and preservation group since its inception, but the tools with which they operate has required little change.

Peace Monument at Lookout Mountain – Chattanooga, Tennessee (National Park Service) *Additional laser treatment powered by Mi-T-M generators.

Arlington National Cemetery

From 1984 – 2006 Ponsford was granted the honor of cleaning and preserving monuments at the Arlington National Cemetery such as the Tomb of the Unknown Soldier and the John F. Kennedy Grave. Mi-T-M pressure washers were an essential tool when it came to cleaning 300,000 white head stones in just 6 months time. That’s 50,000 head stones a month, so you can see why dependability mattered. Protecting these historic landmarks against deterioration and maintaining their integrity is vital for the remembrance and acknowledgment of why they are placed there.

Arlington National Cemetery honors those who have served our nation by providing a sense of beauty and peace for guests of the site. The impressive landscape in Arlington, VA serves as a tribute to the service and sacrifice of every individual laid to rest within the hallowed grounds of Arlington National Cemetery. As a conservation group that operates around the globe, servicing monuments of Arlington National Cemetery is an extremely prestigious opportunity. Decades of experience has given Ponsford the intimate knowledge needed to effectively clean highly valued monuments, statues, and objects.

Hot vs Cold Cleaning Power

All of this experience has led Ponsford to rely on Mi-T-M equipment because of the superior performance it has provided. Hot and cold pressure washers are used to clean these monuments and provide contrasting results. A hot water pressure washer does an amazing job of removing surface mold and other debris from a sculpture without needing to increase the pressure from the washer. This prevents erosion and surface wear that can compromise the structural integrity of the monument or statue and can be costly to repair. Cold pressure washers aren’t used as frequently on delicate surfaces but are used on heavy duty metal surfaces where a sandblasting tip is used for more abrasive applications. A cold-water pressure washer and sandblasting tip is generally used on memorials such as tanks and heavy artillery installations seen at national and local parks.

A Passion And An Honor

Owner Gordon Ponsford says, “having the opportunity to clean monuments and sculptures at such a historic and storied location such as Arlington National Cemetery is one of the highest honors. It is very important to us to preserve and honor our history.”

Mr. Ponsford points out two important reasons why he’s chosen to stay with Mi-T-M products over the years: reliability of the equipment and service from the dealers. Mr. Ponsford’s travels take him across the entire globe but he is always able to find a Mi-T-M servicer wherever he goes. Furthermore, under a federal or government contract there is no leniency with malfunctioning equipment. With Mi-T-M equipment being so reliable, he has never had to look elsewhere.

Accessories

Accessories

Pressure Washers

Pressure Washers

Air Compressors

Air Compressors

Generators

Generators

Air Compressor Generators

Air Compressor Generators

Air Compressor / Generator / Welders

Air Compressor / Generator / Welders

Portable Heaters

Portable Heaters

Water Treatment Systems

Water Treatment Systems

Trailers

Trailers

Water Pumps

Water Pumps

Wet / Dry Vacuums

Wet / Dry Vacuums

All Residential Products

All Residential Products

All Commercial Products

All Commercial Products

Pressure Washers

Pressure Washers

Generators

Generators

Air Compressors

Air Compressors

Custom Fire Pits

Custom Fire Pits

Portable Heaters

Portable Heaters