Whether you’re inflating tires, running air tools in your shop, or powering pneumatic equipment on the jobsite, choosing the right air compressor can make all the difference. Mi-T-M air compressors are built to handle every application, from light commercial use to heavy industrial performance.

This guide will walk you through the key factors to consider when buying an air compressor and help you select the air compressor that best fits your needs.

Understanding Your Application

Before looking at specs or sizes, start with how you’ll use your air compressor. Each job has different air requirements:

- Home or light shop use: inflating tires, nail guns, small tools

- Contractor or construction use: framing guns, impact wrenches, paint sprayers, multiple air tools

- Industrial use: continuous, high-pressure demand for machinery or production environments

Your compressor should deliver enough air (CFM) and pressure (PSI) to power all the tools you plan to use.

Step 1: Know the Key Terms

When comparing air compressors, these are the most important specifications to understand.

CFM (Cubic Feet per Minute)

This measures the volume of air the compressor produces. Add up the air demand (CFM) for each tool you’ll use simultaneously, then choose a compressor that exceeds that number by about 20 %.

PSI (Pounds per Square Inch)

The pressure your compressor can deliver. Most pneumatic tools operate around 90 PSI, but heavy-duty or industrial equipment may require more.

Horsepower (HP)

Determines how much work the motor or engine can perform. More horsepower means faster air recovery and greater capacity.

Tank Size

A larger tank stores more compressed air, allowing tools to run longer before the compressor cycles. For intermittent use, a smaller tank may suffice; for continuous operation, a larger tank is more efficient.

Takeaway: CFM = airflow, PSI = pressure, HP = power, and tank size = runtime. Knowing these specs helps you compare models confidently.

Step 2: Choose Your Power Source

Mi-T-M manufactures both electric and gas air compressors to match your working environment.

Electric Air Compressors

- Ideal for indoor use or areas with easy access to power

- Quieter operation and zero emissions

- Great for workshops, garages, or manufacturing facilities

View Electric Models

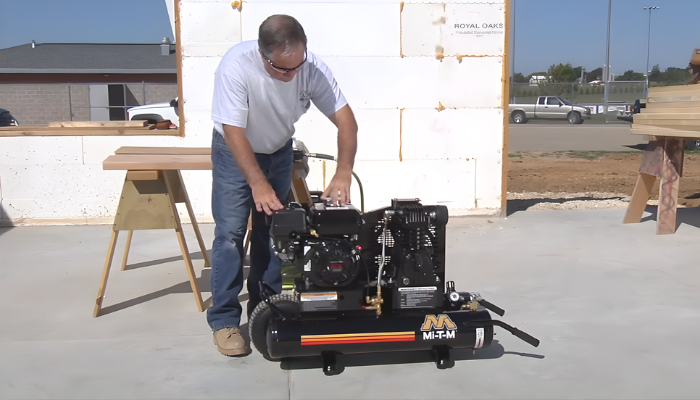

Gas Air Compressors

- Best for outdoor or remote locations without electrical access

- Powerful, portable, and reliable for construction or service vehicles

- Durable engines designed to run in rugged conditions

View Gas Models

Takeaway: Electric compressors are best indoors where power is available; gas models are ideal for outdoor or remote job sites.

Step 3: Select Your Stage – Single vs Two Stage

Mi-T-M offers both single-stage and two-stage air compressors to fit your pressure and performance needs.

| Type | Compression Process | Typical PSI Range | Best For | Key Benefit |

|---|---|---|---|---|

| Single Stage | Air compressed once | Up to 135 PSI | Light commercial & residential | Simple, affordable, easy to maintain |

| Two Stage | Air compressed twice | Up to 175 PSI | Industrial & continuous use | Higher pressure & efficiency |

Takeaway: Single-stage compressors handle light to moderate jobs efficiently; two-stage units are built for higher pressures and continuous use.

Step 4: Decide on Portability and Mounting

Mi-T-M’s compressors are built with heavy-duty frames, reinforced tanks, and corrosion-resistant finishes. Whether you’re rolling it across a jobsite or anchoring it in your shop, you can count on years of dependable service.

| Type | Best For | Benefits |

|---|---|---|

| Portable Compressors | Contractors, field technicians, mobile jobs | Easy to move between job sites; available in wheelbarrow, hand-carry, and truck-mount options |

| Stationary Compressors | Workshops, manufacturing, automotive shops | Larger tanks and continuous-duty power for fixed installations |

Takeaway: Portable models move easily between job sites; stationary units deliver consistent air for dedicated workspaces.

Step 5: How to Size Your Compressor Properly

Choosing the right size air compressor comes down to understanding how much airflow (CFM) and pressure (PSI) your tools require, and making sure your compressor can deliver both comfortably. If you skipped ahead, you can jump back up to “Know the Key Terms” for a quick refresher on what CFM and PSI mean.

1. List Every Tool You’ll Use

Start by writing down each air tool you plan to use, especially if you’ll run more than one at the same time.

| Tool | Avg. PSI | Avg. CFM | How Often You Use It |

|---|---|---|---|

| Impact Wrench | 90 PSI | 5.0 CFM | Frequently |

| Air Ratchet | 90 PSI | 4.0 CFM | Occasionally |

| Paint Sprayer | 40 PSI | 6.0 CFM | Occasionally |

| Blow Gun | 90 PSI | 3.0 CFM | Frequently |

2. Find Your Peak Air Demand

Add together the CFM of all tools you’ll run simultaneously. If you’re unsure, assume two to three tools may run at once, this is common for small shops or crews.

Example:

Impact Wrench (5.0) + Air Ratchet (4.0) = 9.0 CFM

3. Add a Safety Margin

Always give your compressor some breathing room. Multiply your total CFM by 1.25 (a 25% safety factor) to avoid overworking the motor and allow for future tools.

9.0 × 1.25 = 11.25 CFM minimum requirement

So, you’d want a compressor rated at least 11.25 CFM @ 90 PSI.

4. Match PSI Requirements

Each tool lists a recommended operating PSI. Your compressor’s maximum PSI should meet or exceed the highest number on your list.

For example, if all your tools operate around 90 PSI, a 135 PSI single-stage compressor works perfectly.

If you need 150 PSI or higher, a two-stage compressor (like Mi-T-M’s industrial line) is the right choice.

5. Consider Tank Size and Duty Cycle

Your tank size determines how long your tools can run before the compressor refills.

| Tank Size | Typical Use | Run Time Example |

|---|---|---|

| 3–8 Gallons | Nail guns, inflation, DIY | Short bursts |

| 20–30 Gallons | Small shop, 1–2 tools | Moderate runtime |

| 60+ Gallons | Automotive or industrial | Continuous use |

For continuous duty (industrial environments), Mi-T-M’s two-stage stationary units are ideal because they maintain pressure without frequent cycling.

Real-World Example

Let’s say you’re a contractor running two framing nailers (each 4 CFM @ 90 PSI) and a small impact wrench (5 CFM @ 90 PSI):

- Add the CFM: 4 + 4 + 5 = 13 CFM

- Multiply by 1.25: 13 × 1.25 = 16.25 CFM

- Choose a compressor rated at least 16–18 CFM @ 90 PSI

- Since you’re on-site, select a gas-powered, two-stage, portable Mi-T-M unit around 20 gallons.

That setup gives you enough air for all tools, extra capacity for peak loads, and portability for the jobsite.

Takeaway: Add up the CFM of your tools, multiply by 1.25, and choose a compressor that meets that airflow at your highest required PSI.

Step 6: Choosing the Right Mi-T-M Air Compressor

By now, you know how to size your air compressor and understand the key differences between single-stage vs. two-stage and gas vs. electric models. Here’s a simple way to bring it all together, a quick guide to choosing your Mi-T-M compressor based on where and how you’ll use it.

Quick Reference Guide

| Your Situation | Recommended Power Source | Recommended Stage | Typical Tank Range | Ideal Mi-T-M Category |

|---|---|---|---|---|

| Light use around the home or garage | Electric | Single-Stage | 3 Gallon | Residential 3-Gallon Portable |

| Small workshop or contractor with moderate tool use | Gas or Electric | Single-Stage | 5–30 Gallon | Industrial Single-Stage |

| Multiple tools or frequent all-day use | Gas or Electric | Two-Stage | 80 Gallon | Industrial Two-Stage Portable |

| Continuous duty, large shop, or manufacturing environment | Electric (or Gas where needed) | Two-Stage | 80 Gallon | Industrial Two-Stage Stationary |

In Summary

- Electric compressors are best for indoor or shop use where power is available.

- Gas compressors offer flexibility for outdoor or on-site work.

- Single-stage units are simple, affordable, and great for light to moderate use.

- Two-stage units deliver higher PSI and durability for demanding or continuous applications.

Every Mi-T-M air compressor is built for longevity, featuring heavy-duty components, corrosion-resistant finishes, and performance you can rely on — whether you’re in your garage, on a jobsite, or running a busy shop.

Need Help Choosing? Talk to a Mi-T-M Expert

Our team is here to help you find the right fit based on your needs and budget.

Related Videos

Learn directly from Mi-T-M experts with these quick video guides:

Final Thoughts

Selecting the right air compressor doesn’t have to be complicated. By understanding your air requirements, power source, and application, you can easily find the perfect fit within Mi-T-M’s lineup.

Whether you’re a DIY user, contractor, or industrial operator, Mi-T-M delivers the reliability, performance, and durability to keep your operation running smoothly for years to come.

Need Help?

Monday - Friday, 7:30 a.m. - 5:00 p.m. CST

Latest Equipment

Latest Equipment

Accessories

Accessories

Pressure Washers

Pressure Washers

Air Compressors

Air Compressors

Power Generation

Power Generation

Air Compressor Generators

Air Compressor Generators

Air Compressor / Generator / Welders

Air Compressor / Generator / Welders

Portable Heaters

Portable Heaters

Water Treatment Systems

Water Treatment Systems

Trailers

Trailers

Water Pumps

Water Pumps

Floor Care

Floor Care

All Residential Products

All Residential Products

All Commercial Products

All Commercial Products

Pressure Washers

Pressure Washers

Power Generation

Power Generation

Air Compressors

Air Compressors

Custom Fire Pits

Custom Fire Pits

Portable Heaters

Portable Heaters

There are no comments on this post.